FIRE POLY™

(FP 100)

INTERIOR/EXTERIOR FIRE RETARDANT

COATING / SPRAY

FOR ALL WOOD PRODUCTS

PLYWOOD ● LUMBER ● TIMBER ● OSB ● I-JOISTS

FIRE RETARDANT COATING

SURFACE BURNING CHARACTERISTICS OF APPLIED COATING

| Flame spread | <10 lumber. < 5plywood, 0 OSB; 0 I-joist |

| Smoke developed | 125 lumber; 115 plywood; 40 OSB; 80 I-joist |

| Number of preliminary coats | None |

| Rate per coat (ft2/gal) | -- |

| Number of fire retardant coats | 1 |

| Rate per coat (ft2/gal) | 200 |

| Number of overcoats | None |

| Mil thickness | 4 |

| Rate per coat (ft2/gal) | -- |

| Flash point of liquid coating: | |

| Fire retarding coating - closed cup, | no flash |

FIRE POLY™ |

TECHNICAL DATA INTERIOR / EXTERIOR CLASS A FIRE RETARDANT COATING |

|---|

PRODUCT DESCRIPTION: Aqueous Based Resin

| PRODUCT ANALYSIS | ||||

|---|---|---|---|---|

Total Solids |

63% | PH | 1.9 - 2.2 |

|

Weight per gallon |

13.2 - 13.3lbs | Flash point | Non-Flammable |

|

Specific gravity |

1.45 | Color | Milky color liquid - dries clear |

|

Volatability |

Non-Volatile | Solvents | Water(Contains no petroleum or derivatives of petroleum) |

|

Anti-Fungus |

excellent Resistance | Bacterial | Good Resistance |

|

Linear shrinkage |

None | Moisture Absorption | None |

|

Corrosive |

Mildly | Toxic | None (when dry) |

|

Insects, rodents, aspergilli And other types of molds |

Excellent resistance | Termites | Excellent resistance |

|

Preservative for wood |

Good | Scrubability | 1000 cycles |

|

RECOMMENDED USE: Interior/Exterior Class A Rating (Flame spread < 20)

FLAME SAFE FIRE POLY100 is a high intumescent fire retardant coating. It can be used on any type of wood, porous, or non-porous materials, such as:

| Yellow pine | Redwood | Cedar | Douglas Fir | OSB |

I-Joists |

| Maple | Oak | Poplar | Walnut | Trusses |

SYP |

| Cyprus | Mahogany | Teak | Thatching | Trusses |

SPF |

| Bamboo | Koa | Ponderosa Pine | Plywood | Rim Board |

LVL, PSL |

ENVIRONMENTAL REGULATION:

This product complies will U. S. Federal Regulations concerning the use of lead in paint and hydrocarbon emissions.

FIRE POLY™ |

QUICK REFERENCE FOR APPLYING FIRE POLY™ FIRE RETARANT COATING |

|---|

MATERIAL |

APPLICATION |

COVERAGE |

| Exterior/Interior wood any type of wood |

Treat before, during or after construction. Be sure surface is clean and dry before treating. Apply with brush or roller. May be necessary to wipe on hardwood surfaces Treat all surface areas where possible Do not expose treated area to moisture for 24 hours. |

Apply one (1) coat at the rate of 200 sq. ft. per gallon

|

Flame Safe Fire Poly™ high intumescent fire retardant coating swells as a result of heat exposure or flame, converting combustible gases and tars to non-combustible carbon char causing the surface to bubble-up and thereby creating a thermal barrier between the fire and the treated material. The carbon char is a poor conductor of heat, protecting the substrate from being consumed by the fire. |

High Intumescent fire retardant High Intumescent fire retardant |

EXTERIOR / INTERIOR WOOD All surfaces to be treated must be clean

and dry. Fire Poly™ FP100 fire retardant coating is water-based, clear liquid that

becomes insoluble when dry. On exterior wood

Fire Poly™ FP100 can last five years or more, while

maintaining a flame spread index of less than 25.

In extreme weather conditions it may be necessary

to re-coat surfaces every three to five years. It

also acts as a preservative, waterproofing agent,

ultra violet inhibitor, mold and mildew inhibitor, and

it repels insects. If over coating is intended, Fire

Poly™ FP100 fire retardant coating is an excellent surface primer for use under

latex paints, or can be used as a finished coat over

water based stains. Finished surfaces will exhibit

semi-gloss to gloss finish similar to lacquers or

epoxies. Contact parts of any equipment should be stainless steel or plastic to prevent chemical reaction and breakdown. Storage may be done in polyethylene containers. Fire Poly™ FP100 fire retardant coating when applied according to the manufacturer’s specifications is the most effective fire retardant coating available. |

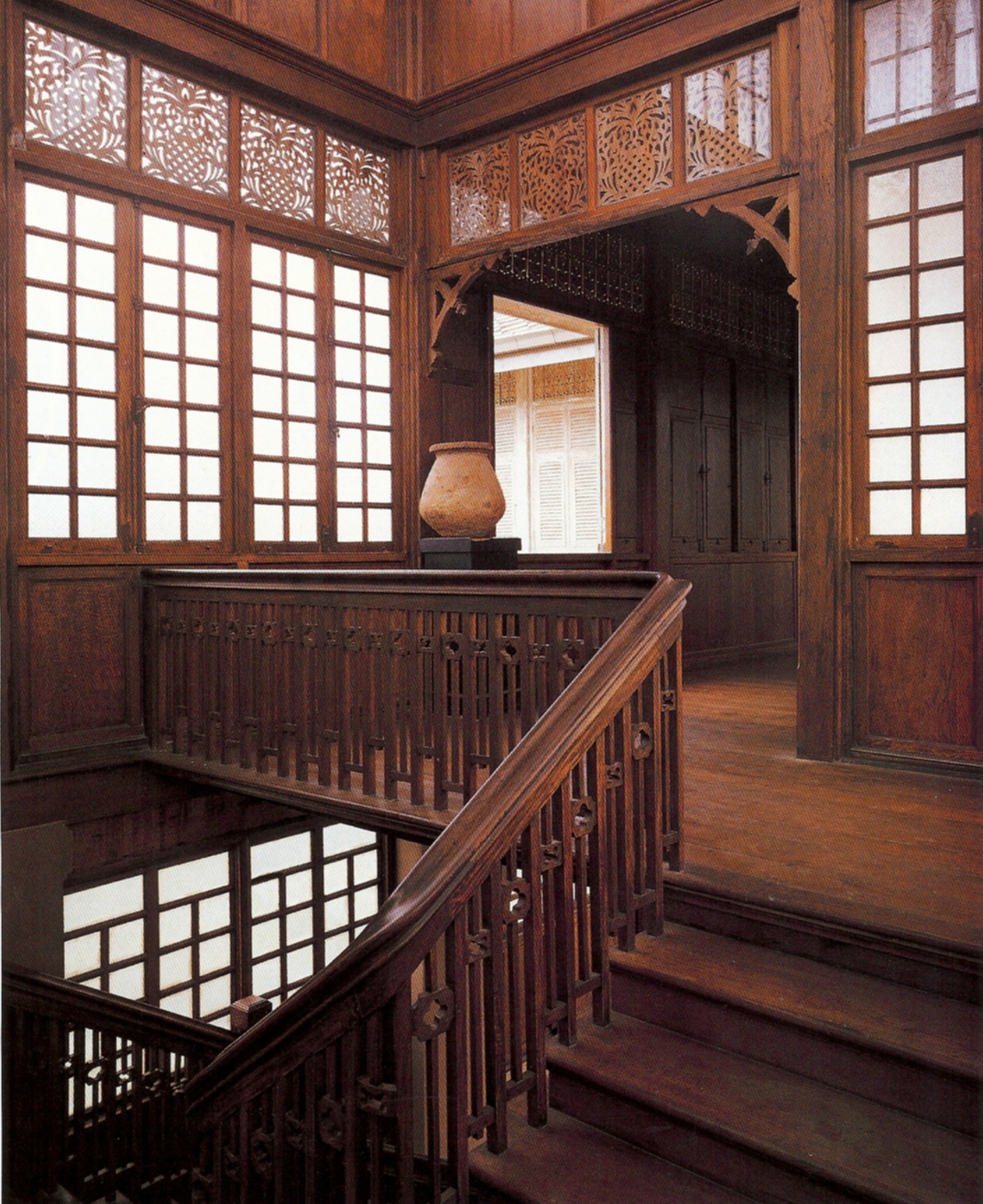

Fire Retardant for Historical Restoration |

|---|

| Call for pricing and ordering 1-800-333-9197 |

CAUTION:

Product must not freeze. It must not be thinned or diluted. Do not apply Fire Poly FP100 below 40°F (4.45°C) or relative humidity conditions greater than 80%.

OVERSPRAY:

The overspray will not harm plants or animals. Spills can be flushed with water. A rag wetted with bleach and water mix will clean up spotting.

CLEAN UP PROCEDURE:

Airless Equipment.

1. Run clear water through the system until coating is flushed out. When minor sudsing on surface stops, the system is flushed.

2. Run bleach and water mix (1 part to 4 parts) through system as solvent for cleaning any residue.

3. Repeat Step 1 if any foaming occurs in Step 2.

4. Lubricate system as specified by equipment manufacturer to combat rusting.

If two or more applications are planned in the same day, the sprayer can be kept clean by running water through the system between applications.

Brushes/Rollers.

1. Clean immediately after use.

2. Wash thoroughly with bleach and water mix (1 part to 4 parts).

SAFETY FIRST

Use approved safety devices (ropes, belts, ridge hooks, ladder, etc.) When working on steep or high areas. Take EXTREME CARE not to step on wet treated area. Surface may be slick until dry.

It is good practice to wear respirator or mask and protect hands with rubber gloves when spraying any coating or chemical. When engineered air control is not feasible, use properly maintained and properly fitted NIOSH approved respirator for solvent vapors. A dusk mask does not provide protection against vapors.

If eye contact occurs, flood with water for fifteen (15) minutes and call a physician. KEEP OUT OF REACH OF CHILDREN. DO NOT TAKE INTERNALLY.

|

|

|---|

| Call for pricing and ordering 1-800-333-9197 |